Forgot Username? Forgot Password?

Forgot Username? Forgot Password?

H. N. White KING - 1934 Back to Factory Tours

June 30, 1934 - Altoona, PA. Junior Band, under the baton of F.C. Hager, giving an outdoor concert in front of The H. N. White Company offices, after a most interesting visit through their factory.

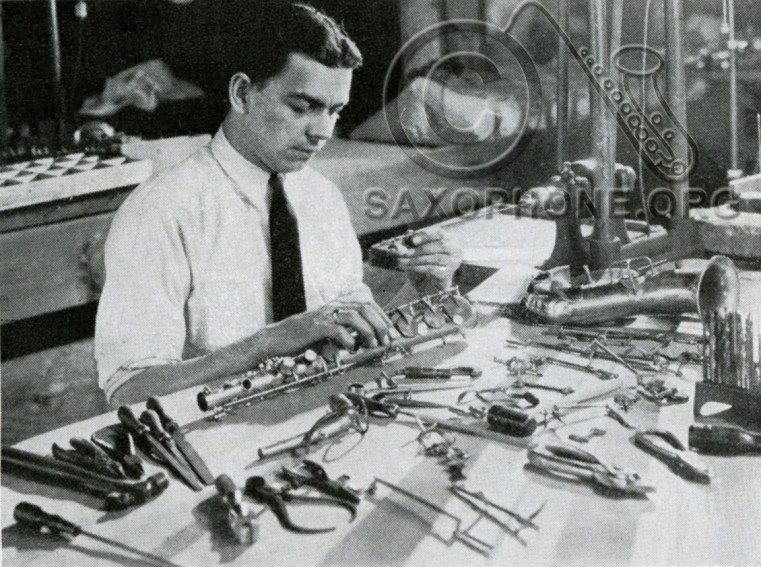

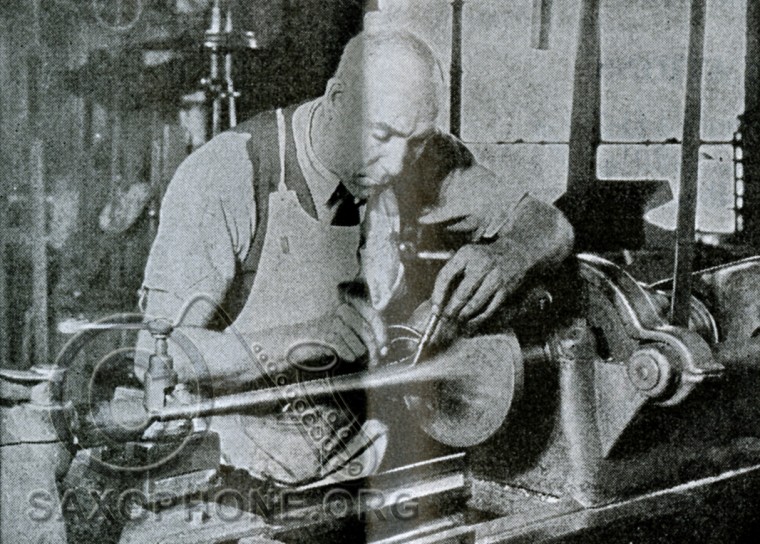

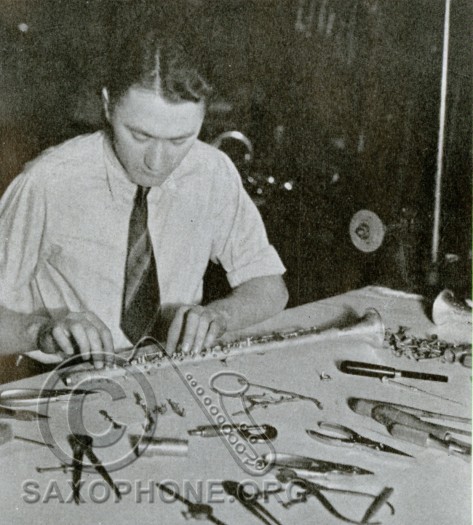

Saxophone Assembly Department. Here saxophones are hand assembled. Each part is carefully fitted so as to provide a smooth and even feel up and down the registers.

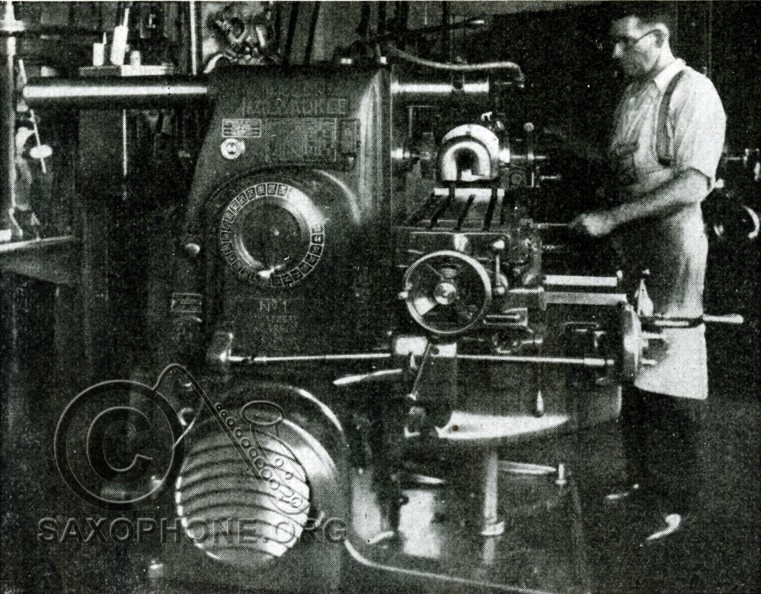

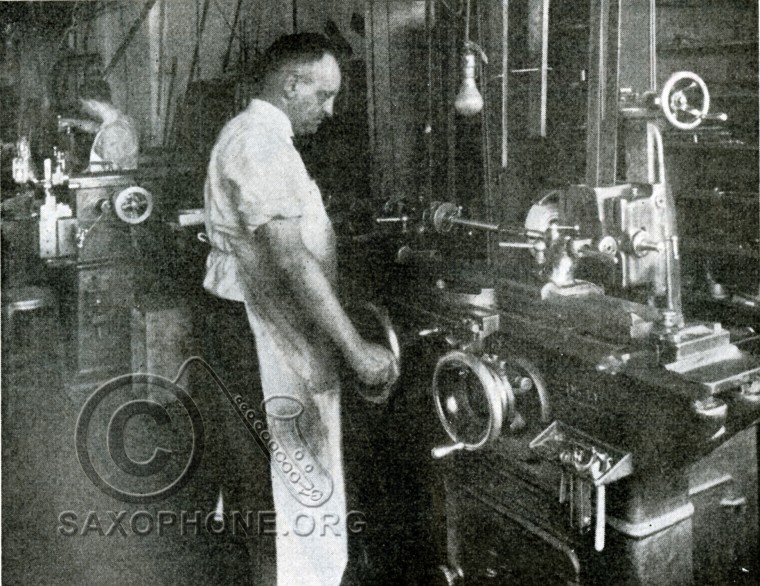

Section of the Tool and Die Making Department, showing a full universal milling machine. With this machine the tool maker was able machine and shape a block of steel to any dimension or design required for making tools and dies necessary to produce uniform parts for instruments. This fine machine tool was one of the latest additions to the King factory in 1934 and was without question a state of the art piece of machinery.

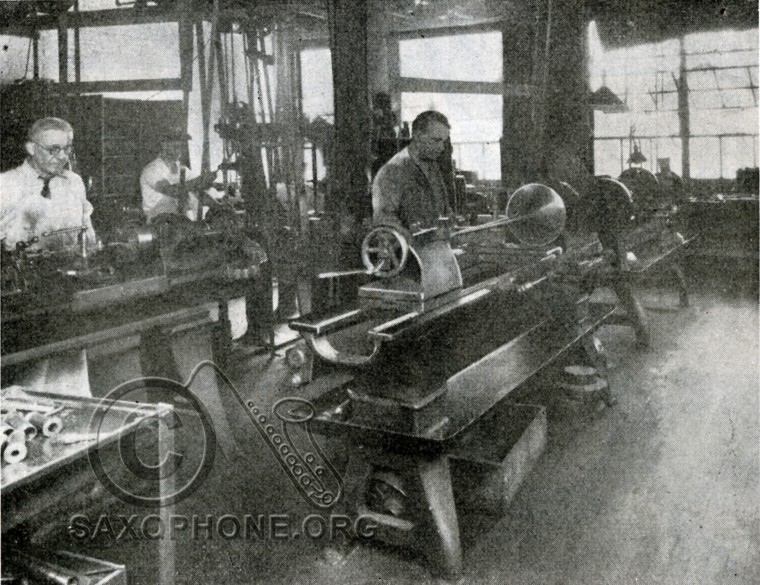

Section of the Lathe Department in the tool room. Front view showing operation of shaping a steel bell mandrel. This illustrates the micrometer accuracy required, for the contour of the mandrels used in shaping the bell section of an instrument must be held to absolute accurate dimensions.

Section of the Lathe Department in the tool room. Close-up view showing operation of shaping a steel bell mandrel. This illustrates the micrometer accuracy required, for the contour of the mandrels used in shaping the bell section of an instrument must be held to absolute accurate dimensions.

Section of the Tool Room, showing cylindrical and surface grinding equipment. First view showing operation of grinding spiral reamer used in reaming valve cases. On this full universal tool and grinding machine the diameters and sizes of mandrels, reamers and punches can be ground to very accurate dimensions. Sizes can be held to the limits as close as 1/10000 part of an inch.

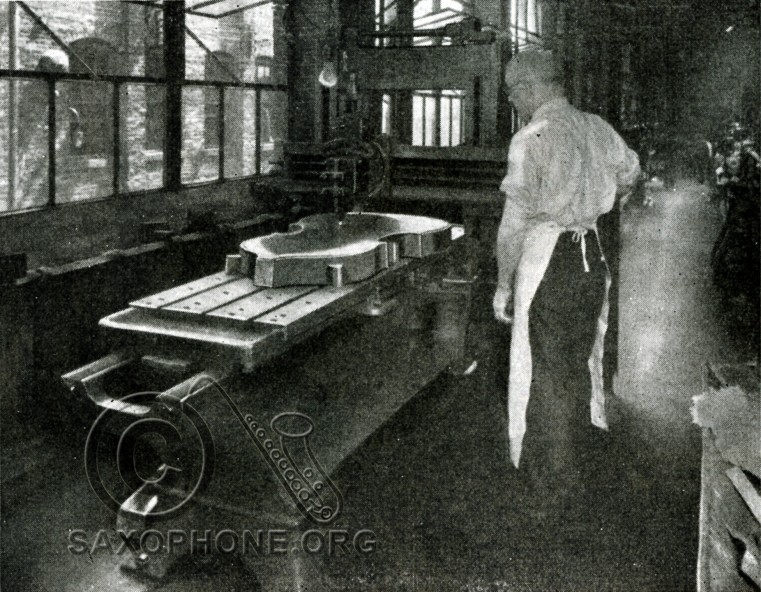

Showing the operation on a large planer of machining the surface of large matrix die used in the manufacture of stringed basses. This machine will plane and surface a block of steel or iron 6' long x 2' wide to a perfectly true surface within limits of 2/1000 parts of an inch.

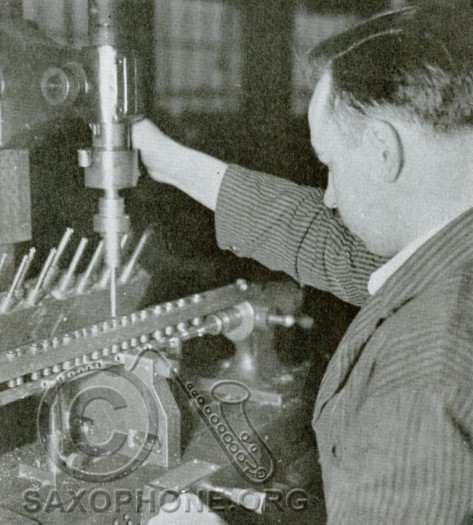

Machine designed for the accurate drilling of tone holes. The master bar shown above the clarinet body guides the cutting tool accurately. Location and size of tone holes is essential in building a clarinet of perfect intonation.

King Clarinet bodies must pass careful inspection after tone walls and key support posts are silver soldered in place. Walls require a certain height for correct pitch and posts proper location for easy key action.

Only expert workmen, with years of experience, are to be found assembling King clarinets. A finished King clarinet embodies every good feature required by any artist.

King clarinet keys are made of a special alloy of white silver. This metal is very hard, but pliable. The keys do not bend out of place or break. One of the most important items in in making a high grade clarinet is the key system.